Cutting Station Defaults File - WM2 8

- From the main warehouse menu, enter WM2 8 to access the Cutting Station Defaults File Maintenance screen.

- To add a workstation, press F1. To update an existing cutting station, enter a U in the Opt column of the cutting station you want to change. Press Enter to access a screen that enables you to assign locations, decide when not to make a cut, and a level to scrap or ship the remaining inventory.

- Press F11 to proceed to the second screen.

- Press F11 to proceed to screen 3.

A workstation is designated as a cut station by entering a C in the Work Station Type field at the bottom of page three of the Workstation Control Panel File Maintenance Screen.

| Field | Description |

| Default Location representing the cutting machine, pre-Cut | This field assigns a location for the roll when it is placed into the hopper before it is cut. |

| Default Location representing the cutting machine, post-Cut | This location pertains to the cut piece that is going to be shipped to the customer. |

| Roll Balance Location | This is the location where the unused part of the roll is returned prior to going back to stock. |

| Maximum size of roll balance (after cut) to suggest that operator Ships the Balance rather than Cutting | This field sets the maximum amount of inventory left on the roll to avoid cutting it. For example, if this field is set to 5 FT and after cutting there would only be 4 feet left the system alerts you that the roll should not be cut. The correct settings here can save you cutting costs and time. If this field is left blank, this parameter is ignored. |

| U/M of above Maximum | The unit of measure used to calculate the maximum size roll balance. |

| Adjustment Code for Shipping Balance | This code reconciles the excess inventory that is being sent with the order. Some of the codes are system defined, but you can define as many new ones as you need. |

| Maximum size of roll balance (after cut) to suggest that operator Discards the Balance after cutting | If, after cutting, the balance of a roll falls under this entry the balance will be scrapped. If the balance is over this entry it will be returned to inventory. If this field is left blank, this parameter is ignored. |

| U/M of above Maximum | The unit of measure used to calculate the remainder of inventory left on the roll. |

| Adjustment Code for Discarding Balance |

This code tells the system the reason why the remaining inventory on the roll was discarded. The system then makes the necessary inventory adjustments. Some of the codes are system defined, but you can define as many new ones as you need. To display a listing of all the codes, enter a ? in the field and press Enter. |

| Field | Description |

| Work Station (Cutting) | If you are adding a new cutting station enter its identifier here. If this is an existing cutting station that you are updating the current code is displayed. |

| Default Label Output Queue | This field allows you set a default printer for printer labels. |

| Auto-Generate new Serial# Tag for each roll balance after Cut | Flagging this option to Y directs the system to automatically create a new serial number tag for each roll after a cut is made. |

| Default Label Output Queue for Serial# Tag | This field allows you set a default printer for serial number tags. |

| Auto-Generate new Cut Order Roll License Plate after Cut | Flagging this option to Y directs the system to automatically create a new LPN for each roll after a cut is made. |

| Default Label Output Queue for Cut Order Roll License Plate | This field allows you set a default printer for LPNs. |

| Auto-Prompt Operator to handle a measured balance | Flagging this options with a Y directs the system to automatically perform the function after there are to be no more cuts made on a roll. |

| Enter FT Minimum length to trigger asking for a measured balance | If the quantity of a roll falls below the amount entered here the system prompts the operator to measure the remainder of the roll. |

|

Status code for Cut Station Status Change Screen Prevent this status code from being changed |

The default order status code for the order line being cut. Setting a default status code can prevent operator mistakes.

Prevents an operator from changing the default status code. |

|

Number of Inches to Add to Every Cut Adjustment Code for number of Extra inches added to the cut |

Adds an additional set number of inches to every cut. You can use this to compensate for cutting machines that are out of calibration. |

| Is this Cut Station in a Non-RF environment | If this flag is set to Y, then the cut station is considered to be in a non-RF enable warehouse. The inventory is still moved the same as it would be in an RF enabled warehouse, however the application does it as the cut is made in the status update program. The balance is always moved back to the location that it was taken from, and allocated against prior to the cut. |

| Cut Machine Host Table Name Entry |

This is used if the cut station has been equipped with an electronic interface to pass the cut length from the order. This value is the name for the cut station in the WRKCFGTCP option which identifies the IP address of the cut station interface. |

| Start All Cuts with sending cut length to cut machine |

This field enhances the use of the cut stations that use cut machine interfaces that receive the length of the cut to be made for an order line. When the order line barcode is scanned, the length is sent electronically to an interface on the cutting machine, the type of interface varies by machine and is controlled in the system wide settings (SET 004). Activating this field, directs the system to start the cutting process by prompting for the order line. The order line is processed and the length is sent to the cut machine interface. The program then continues to ask for the badge, serial number, or whatever is required for the work station. If this field is not activated, the length isn't sent until the status code is entered, because there is no transmission of data from the workstation to the server until the screen has all the required fields populated. |

| Is this Cut Station in a Non-RF environment? | If this flag is set to Y, then the cut station is considered to be in a non-RF enable warehouse. The inventory is still moved the same as it would be in an RF enabled warehouse, however the application does it as the cut is made in the status update program. The balance is always moved back to the location that it was taken from, and allocated against prior to the cut. |

| Highlight order lines in these status codes on the cut screen |

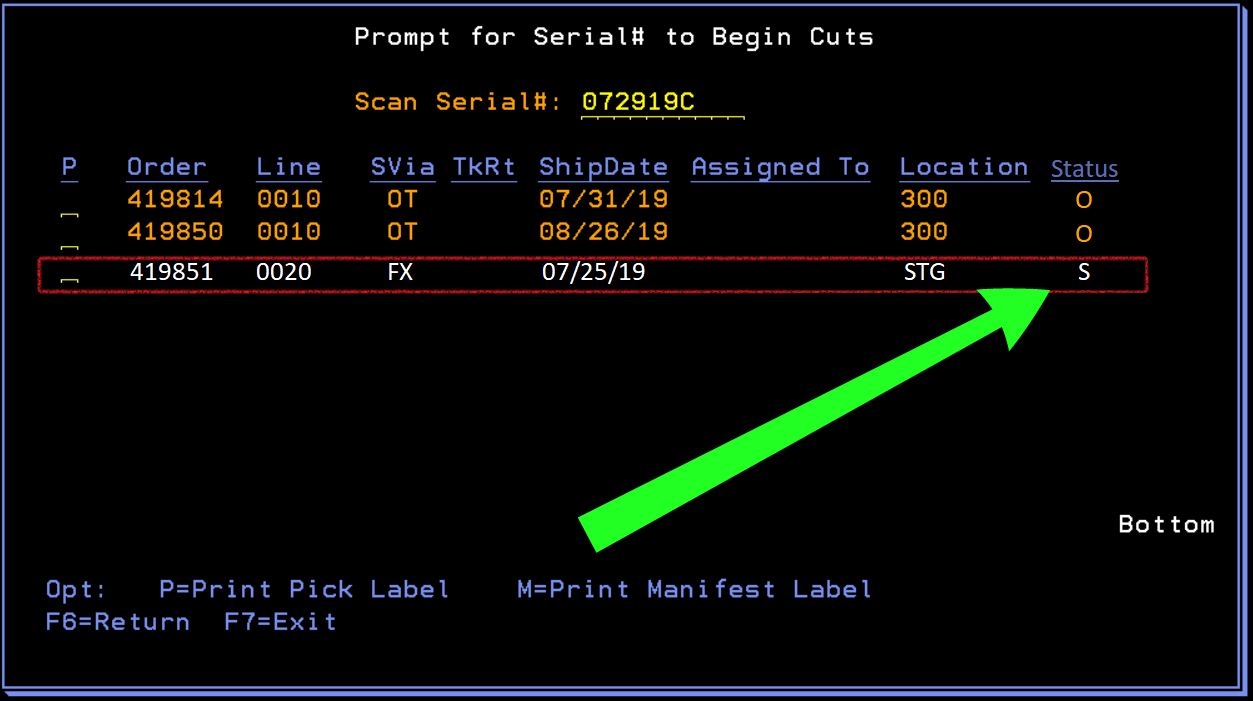

This setting, introduced in Sept 2019 via spec 6032, allows cut table operators to see the order status without having to refer back to the order. It allows you to be able to highlight orders on the Prompt for Serial# to Begin Cuts (WAR 5>F4) window for easy recognition.

|

| Field | Description |

| Multi-Cut Window Parameters | |

| Show Will Calls orders as potential additional cuts? | Enter a Y to display will call orders in the multi-cut window. |

| Number of Days to Show ahead for potential additional cuts | Determines the number of days from the ship date that orders appear on the multi-cut station display. This setting provides you with more inventory control over multi-cut material at your cut station. |

| Show Credit Held Orders in Multi-Cut Window? | Enter a Y to show credit held orders on the multi-cut window. Letting the cut station operator see credit held orders allows for communication between the warehouse and the credit department to solve potential problems. For example, either the credit issue can be resolved or the ship date can be changed. |

|

If Label Printed. ( ) Show None (1) Show Same S/N (2) Show All |

Gives you more control over the orders that appear on the multi-cut display. The default is to not show orders that have already had labels printed, leaving the field blank. This can eliminate potential duplicate cuts for the same order. If a 1 is entered, only items with the same serial number as those printed on a label appear. Entering a 2 allows for all items that have a label printed to display at the multi-cut window. This option gives the operator control over what is cut. |

| F1 Menu Parameters | |

|

Adjustment Code for Cut Station Menu, Option 4 - Quantity Adj Prevent this Adjustment code from being changed |

Establishes a default status code for option 4 - Subtract Quantity from Roll Balance on the Cut Station Functions menu. Setting a default status code can prevent operator mistakes. Prevents an operator from changing the default status code |

|

Adjustment Code for Cut Station Menu, Option 5 - Endout Prevent this Adjustment code from being changed |

Establishes a default status code for option 5 - Write Off Balance on the Cut Station Functions menu. Setting a default status code can prevent operator mistakes. Prevents an operator from changing the default status code |